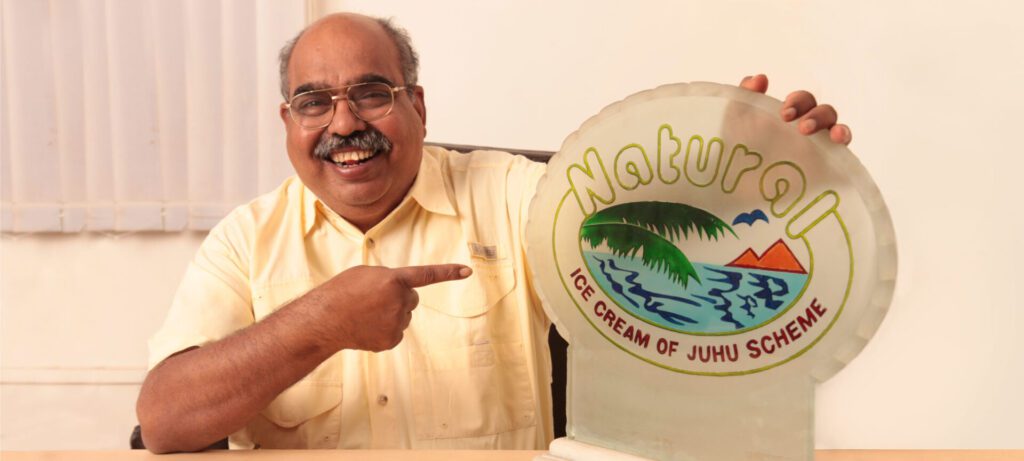

Unforgotten Brands – Naturals Ice Cream

Raghunandan’s relentless pursuit of excellence and customer-centric approach ensured Naturals’ enduring success

On the one-acre plot of land around his mud-and-straw dwelling, where he resided with his wife Shantabai and seven children, Srinivas—a trader hailing from Mulki in South Kanara—grew a variety of fruits. In 1954, Raghunandan came into this world as the youngest.

During the hot summer months, Srinivas Kamath would smell the aroma of ripe mangoes and then choose the best ones to sell in the market.

Raghunanadan would frequently join his father on fruit-picking trips and later sell them in the market. During this time, he honed his ability to identify ripe apples of exceptional quality. Growing up with his dad taught him all about fruits: how to choose them, how to store them, and when to eat them when they’re ripe.

However, a love for mangoes was no assurance of financial success. There were several problems, including theft, a lack of labour, and poor payments; the produce was seasonal.

The lack of proper maternity care in the hamlet caused Raghunandan’s loss of two siblings. On occasion, seven or even eight members of his family would have typhoid, and there would be no funds to provide them with medication.

Lack of Schooling

Despite the financial hardship, the children enrolled in the community’s sole school.

Unfortunately, nobody was around to see how far they had come. Ragunanadan spent a great deal of time in the forest, harvesting cashews, herding animals, and generally enjoying rural life as a youngster.

Travelling to Bombay for extended periods to attend his sisters’ weddings caused him to further neglect his academics.

This led to his failure in seventh grade on two occasions.

Mother’s Influence

When he got home, he surrounded his mother and watched in awe as she prepared meals using traditional methods. In those days, there was no television at their house. He watched her every move as she delicately peeled fruits and veggies, added spices, and cooked them on the stove. He had no idea what he had learned as a child. Key to his subsequent judgements with Naturals was his admiration and study of his mother’s skills and mindset.

Raghunandan went to live with his brothers in Bombay in 1966, when he was twelve years old. Before his arrival, the brothers had relocated to pursue careers in the hospitality sector.

The English curriculum was too tough for Kamath, and he failed the tenth board examination three times before he gave up and dropped out.

Gokul

By that point, his brothers had built a little Udupi restaurant named Gokul, which sold ice cream in addition to the usual menu of idli, dosa, and other South Indian dishes. This was just one of many eateries that his brothers had started.

Ice cream was a minor and unimportant aspect of their business.

Rather than entrusting Raghunandan with crucial duties, his brothers assigned him to serve ice cream, perceiving him as carefree and youthful due to his lack of seriousness at school.

However, ice cream was not a trivial matter in Raghunandan’s thoughts. While all the Mangaloreans in Bombay who were into hospitality were building Udupi restaurants, he thought Gokul should carve out a special place for ice cream.

He yearned for a change of pace. Unfortunately, none of his brothers took him seriously, and he lacked the self-assurance to counter their arguments.

Entrepreneur

He dared to support his entrepreneurial dream in 1983, after tying the knot at the age of 29.

The brothers were making arrangements to split up. With the newfound freedom, he borrowed Rs 3.5 lakh from family and friends and set out on his entrepreneurial journey.

The Origins of Naturals

Raghunandan revolutionised ice cream consumption in India with a single, straightforward inquiry. “Why can’t we use actual fruits instead of fruit flavours in ice cream?” he pondered. He decided to start his own ice cream shop.

Ice cream was a treat in the 1980s, a decade before liberalisation took hold. The homemade kulfi was a similar and easily accessible frozen delicacy.

There were four brands in the branded segment: Vadilal, Kwality, Joy, and Volga.

Most eateries offered ice cream. In that era, parlours were practically nonexistent. Yankee Doodle was the only one in Bombay, and it wasn’t even a parlour—it was part of Hotel Natraj.

Despite this, Kamath dared to open a shop for ice cream.

He was hoping for a different kind of customer—one who was knowledgeable and wealthy—to come in for ice cream. He set up his business in Juhu, a wealthy district in western Mumbai where many people from the Bollywood industry reside, because he knew that’s where he would find the correct audience.

In 1984, he founded Naturals with the help of his capable wife, Annapurna. Naturals became a name that genuinely reflected his intuition. Naturals produced five original flavours: Sitaphal (custard apple), Kaju-Draksh (cashew-raisin), mango, strawberry, and chocolate.

He found a 400-square-foot storefront in Juhu, which was located away from the hustle and bustle of the main Juhu district and had cheaper property costs. Back then, having enough parking was crucial, as customers preferred to receive service in their automobiles.

However, the likelihood of the concept’s success was a source of concern for him. Is it possible that there is no ice cream culture, so people don’t come in just for themselves?

Kamath offered pav bhaji alongside the ice cream as a precaution against this type of risk.

People were sure to appreciate a refreshing dessert following the hot main course. So that’s how he got them to try his ice cream.

The production area was located at the back of the store, with the 200 square feet at the front dedicated to serving. Six tables were set up on the verandah for seating.

He made five lakh rupees in a year thanks to the pav bhaji—ice cream tactic.

But it wasn’t good enough for Kamath.

What if pav bhaji becomes more popular than ice cream? That was his main worry. The idea was to make ice cream more respectable. When used properly, they bring out the fruits’ natural splendour.

In 1985, he made a bold decision to stop serving pav bhaji.

He not only established the idea of an exclusive ice cream parlour in Bombay with this move, but he also ended up developing a new niche for natural ice creams comprised of three simple ingredients: milk, sugar, and fruit.

Customer Focus

The parlour attracted the type of clientele that Kamath had foreseen.

Raj Kapoor, Shabana Azmi, Dimple Kapadia, Jaya Bachchan, and many more became clients.

Clients would provide Kamath with business advice and suggestions.

He introduced flavours like watermelon and musk melon over time because customers would come and say, “We went to this country and tried this flavour.”

He began producing a new type of mango, which he dubbed pickled mango, whereas everyone else only made Alphonso mango.

A client proposed the name Wild Mango. People were more interested in buying Wild Mango than Alphonso because of how good it tasted and how appealing the name was.

To maintain year-round consistency in fruit quality and ice cream flavour, Kamath would exclusively buy fruits from their respective growing regions.

Innovations

Even as a little boy, Kamath saw that while his mother was boiling milk, she would gently blow air on top of the pot to keep it from boiling over. To keep the milk from spilling out of the kettle, Kamath had engineers develop a system that relied on air pressure.

Based on his observations from childhood, Kamath invented the sitaphal seeder. The process of separating stones from rice, according to Kamath’s memory, involved his mother stirring the rice in water so that the heavier particles would sink and the lighter ones would float. He based the deseeder’s design on this centrifugal force.

Kamath moved the production plant to Mira Road from Juhu because of all the visits the Juhu premises were getting.

A family member’s departure from Naturals to launch an ice cream shop left Kamath feeling down and out. The fact that the relative was privy to all of the formulas and trade secrets posed a danger to Naturals. He maintained his motivation and came up with a formula for a delicate coconut ice cream taste at this time.

To save the trouble and effort of cutting coconuts, Kamath invented a hydraulic coconut cutter. Now anyone can manufacture pulp from coconuts. Tender coconuts are great because they grow all year round, unlike other fruits that are only available at certain times of the year.

Natural is known as an enthusiastic organization about technology, and Kamath has successfully used technology to make ice cream.

Rather than being scared off by the arrival of international rivals like Baskin-Robbins in India, Kamath discovered that ice cream could be transported across great distances.

Franchise Concept

Naturals quickly implemented the franchise concept. Friends and acquaintances who had faith in the brand were the first to get franchises. Franchises were also only available to those who already owned property.

The Natural set the pricing for the franchisee and did not charge any brand fees or royalties. Proceeds from the franchisees’ purchases went to the brand. The profit margins for naturals were somewhat low, ranging from 5% to 10%. Additionally, the franchisee provided daily distribution at no cost, tailored to their specific needs. A minimum order system was not in place. Because of this, stores were able to keep their working capital open, reducing the risk of inventory accumulation and deterioration. Franchisees liked the fact that there couldn’t be more than two or three miles between any two Naturals stores.

After seeing success with the franchise concept, Naturals decided to expand nationally. The freezing machine was the unwavering focus of Naturals during 2000 and 2001. It found batch freezers that could simultaneously whip and freeze ice cream. It eliminated the need for the motorised churner, and by automating the freezing process using Freon gas, Naturals eventually eliminated a time-consuming manual step.

Due to insufficient cold chain facilities in the early 2000s, Kamath depended on India’s extensive rail network. Even if the train was late, Kamath made sure the ice cream wouldn’t melt by designing insulated containers. In 2006, Naturals implemented a Falling Film Evaporator (FFE), which increased the condensing time from 25 minutes for 40 litres of milk to 1 hour for 1000 litres. This resulted in a significant acceleration of their speed.

Helping Workers and Partners

Workers at the plant enjoy a free scoop of ice cream every Wednesday. Naturals provided coupons for restaurants and stores like Big Bazaar and McDonald’s to help industrial workers get a feel for retail culture. Therefore, they were encouraged to expand their perspectives and explore diverse experiences.

Naturals made sure that its business associates flourished as well. Instead of just finding a new milk supplier, Kamath opted to put money into helping its dairy partner become more modern and expand. Kamath also trained fruit dealers and brokers to understand consumer tastes. As part of its transition to digital operations, Naturals educated its vendors on digital banking and cheque payments.

Conclusion

New entrants can easily join this market. One of the major reasons for gaining repeat customers, though, is by offering the greatest quality and making sure clients don’t suffer from throat infections or other worries. The uniqueness and high quality of its ice creams are the main reasons for its appeal.

Kamath would abandon everything, ask obnoxious questions, and inspect various stores, supermarkets, and even Natural’s parlours to see how quickly and effectively they handled customer service. He tells his boys about the criticism and gives them the option to take his advice or not.

Raghunandan’s relentless pursuit of excellence and customer-centric approach ensured Naturals’ enduring success, setting new standards in the Indian ice cream industry.

1 Comment